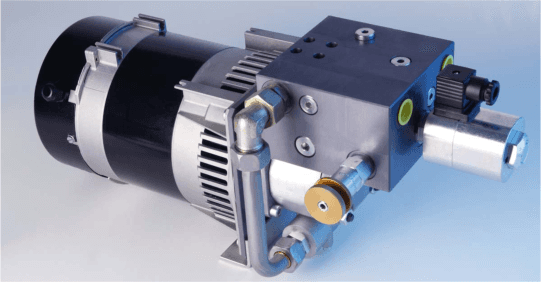

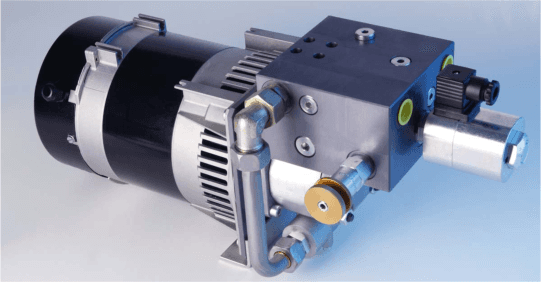

Hydraulic Generator

I recently had a customer call me about a problem he was having with his hydraulic generator

, basically it was running a little bit irratic when first started each morning, now clearly a mechanical flow control valve has limitations as to it's regulation accuracy, but based on the information available the regulation was extremely irratic and unusual. We tried swapping out the flow control valve to no avail, there was no improvement at all, so I suggested that the oil temperature when the machine was cold could be the cause of the problem, the hydraulic generator was fitted to an access platform and on a construction site with an outside temperature of about -7 degrees centigrade, so I suggested running the generator on a small load for a few minutes to warm the oil, sure enough 5 minutes later it was running as it should, problem solved!

This got me thinking about other solutions to eliminate this problem, having supplied diesel engine generators from the Artic to the Antartic over the last 30 years there had to be a solution, on a diesel generator we'd simply use a tank heater and a sump heater to ensure the oil and fuel were kept at appropriate temperatures, I guess the same could be adopted on Access Platforms or anywhere else a hydraulic generator might be installed. But perhaps the problem could be resolved simply by using the correct oil for the conditions, so I did a bit of digging on Google and sure enough in many parts of the world, in particular North America where temperatures vary greatly from Summer to Winter swapping oil is common place, although it would seem that opting for a multigrade oil is negating the need to change oils as they perform at a wide range of temperatures.

What I discovered is that not only do multigrade oils offer better performance relative to temperature variations but that they can also reduce fuel consumption, emissions and wear and tear, oils that are too viscous (thick) take more energy to pump, leading to higher fuel consumption and therefore higher emissions and more wear and tear as they lubricate less efficiently.

So perhaps the solution, especially with the extreme cold weather we have been experiencing in the UK over the last month or so is to look at what hydraulic oil is being used, no matter how you regulate the flow to a hydraulic generator, mechanical or electro-proportional it doesn't fundamentally change the viscosity of the oil being fed to the hydraulic generator, the performance of the oil will not change.

For more information about Hydraulic Generators visit hydraulicgenerators.co.uk

For information about the hydraulic fluids click here Hydraulics and Pneumatics

This got me thinking about other solutions to eliminate this problem, having supplied diesel engine generators from the Artic to the Antartic over the last 30 years there had to be a solution, on a diesel generator we'd simply use a tank heater and a sump heater to ensure the oil and fuel were kept at appropriate temperatures, I guess the same could be adopted on Access Platforms or anywhere else a hydraulic generator might be installed. But perhaps the problem could be resolved simply by using the correct oil for the conditions, so I did a bit of digging on Google and sure enough in many parts of the world, in particular North America where temperatures vary greatly from Summer to Winter swapping oil is common place, although it would seem that opting for a multigrade oil is negating the need to change oils as they perform at a wide range of temperatures.

What I discovered is that not only do multigrade oils offer better performance relative to temperature variations but that they can also reduce fuel consumption, emissions and wear and tear, oils that are too viscous (thick) take more energy to pump, leading to higher fuel consumption and therefore higher emissions and more wear and tear as they lubricate less efficiently.

So perhaps the solution, especially with the extreme cold weather we have been experiencing in the UK over the last month or so is to look at what hydraulic oil is being used, no matter how you regulate the flow to a hydraulic generator, mechanical or electro-proportional it doesn't fundamentally change the viscosity of the oil being fed to the hydraulic generator, the performance of the oil will not change.

For more information about Hydraulic Generators visit hydraulicgenerators.co.uk

For information about the hydraulic fluids click here Hydraulics and Pneumatics

I recently had a customer call me about a problem he was having with his hydraulic generator

, basically it was running a little bit irratic when first started each morning, now clearly a mechanical flow control valve has limitations as to it's regulation accuracy, but based on the information available the regulation was extremely irratic and unusual. We tried swapping out the flow control valve to no avail, there was no improvement at all, so I suggested that the oil temperature when the machine was cold could be the cause of the problem, the hydraulic generator was fitted to an access platform and on a construction site with an outside temperature of about -7 degrees centigrade, so I suggested running the generator on a small load for a few minutes to warm the oil, sure enough 5 minutes later it was running as it should, problem solved!

This got me thinking about other solutions to eliminate this problem, having supplied diesel engine generators from the Artic to the Antartic over the last 30 years there had to be a solution, on a diesel generator we'd simply use a tank heater and a sump heater to ensure the oil and fuel were kept at appropriate temperatures, I guess the same could be adopted on Access Platforms or anywhere else a hydraulic generator might be installed. But perhaps the problem could be resolved simply by using the correct oil for the conditions, so I did a bit of digging on Google and sure enough in many parts of the world, in particular North America where temperatures vary greatly from Summer to Winter swapping oil is common place, although it would seem that opting for a multigrade oil is negating the need to change oils as they perform at a wide range of temperatures.

What I discovered is that not only do multigrade oils offer better performance relative to temperature variations but that they can also reduce fuel consumption, emissions and wear and tear, oils that are too viscous (thick) take more energy to pump, leading to higher fuel consumption and therefore higher emissions and more wear and tear as they lubricate less efficiently.

So perhaps the solution, especially with the extreme cold weather we have been experiencing in the UK over the last month or so is to look at what hydraulic oil is being used, no matter how you regulate the flow to a hydraulic generator, mechanical or electro-proportional it doesn't fundamentally change the viscosity of the oil being fed to the hydraulic generator, the performance of the oil will not change.

For more information about Hydraulic Generators visit hydraulicgenerators.co.uk

For information about the hydraulic fluids click here Hydraulics and Pneumatics

This got me thinking about other solutions to eliminate this problem, having supplied diesel engine generators from the Artic to the Antartic over the last 30 years there had to be a solution, on a diesel generator we'd simply use a tank heater and a sump heater to ensure the oil and fuel were kept at appropriate temperatures, I guess the same could be adopted on Access Platforms or anywhere else a hydraulic generator might be installed. But perhaps the problem could be resolved simply by using the correct oil for the conditions, so I did a bit of digging on Google and sure enough in many parts of the world, in particular North America where temperatures vary greatly from Summer to Winter swapping oil is common place, although it would seem that opting for a multigrade oil is negating the need to change oils as they perform at a wide range of temperatures.

What I discovered is that not only do multigrade oils offer better performance relative to temperature variations but that they can also reduce fuel consumption, emissions and wear and tear, oils that are too viscous (thick) take more energy to pump, leading to higher fuel consumption and therefore higher emissions and more wear and tear as they lubricate less efficiently.

So perhaps the solution, especially with the extreme cold weather we have been experiencing in the UK over the last month or so is to look at what hydraulic oil is being used, no matter how you regulate the flow to a hydraulic generator, mechanical or electro-proportional it doesn't fundamentally change the viscosity of the oil being fed to the hydraulic generator, the performance of the oil will not change.

For more information about Hydraulic Generators visit hydraulicgenerators.co.uk

For information about the hydraulic fluids click here Hydraulics and Pneumatics